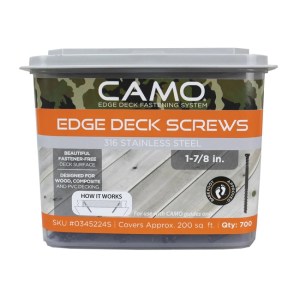

Stainless Steel Screws

Showing all 20 resultsSorted by popularity

-

Price range: £3.35 through £46.51 Inc Vat. Select options This product has multiple variants. The options may be chosen on the product page

-

Price range: £3.20 through £68.32 Inc Vat. Select options This product has multiple variants. The options may be chosen on the product page

-

Price range: £14.96 through £73.90 Inc Vat. Select options This product has multiple variants. The options may be chosen on the product page

-

Price range: £4.43 through £55.82 Inc Vat. Select options This product has multiple variants. The options may be chosen on the product page

-

Price range: £2.99 through £31.68 Inc Vat. Select options This product has multiple variants. The options may be chosen on the product page

-

Price range: £5.26 through £33.50 Inc Vat. Select options This product has multiple variants. The options may be chosen on the product page

-

Price range: £24.64 through £29.60 Inc Vat. Select options This product has multiple variants. The options may be chosen on the product page

-

Price range: £21.50 through £34.61 Inc Vat. Select options This product has multiple variants. The options may be chosen on the product page

-

£2.30 Inc Vat. Select options This product has multiple variants. The options may be chosen on the product page

Showing all 20 resultsSorted by popularity

When you’re working on site, exposed to the elements or building for the long haul, you need fixings you can trust. Our selection of stainless steel screws is built with tradesmen in mind: corrosion-resistant, durable and ready to perform whether you’re indoors, outdoors, in wet zones or high-use areas.

Stainless steel screws are renowned for their strength and longevity, ideal for jobs where rust, moisture or visible fixings are a concern. From 304-grade (A2) for general use to 316-grade (A4) for coastal or chemically exposed environments, you’ll find the right specification for the job. We stock variants across timber-fix, metal-fix, chipboard, self-drilling and coach screws, covering the full spectrum of trade applications.

Whether you’re securing timber boards, installing cladding, fixing metal frames, working on decking or simply making sure that visible fixings look smart and stand the test of time, our stainless steel screws won’t fail you. The benefits are clear: less risk of staining, fewer bolts pulling loose through corrosion, and fewer call-backs to re-fix rusted fixings.

Choose from trade packs, bulk boxes, a range of head types (countersunk, pan head, hex, Torx) and drive systems to match your tools and style of working. Stock up today and make sure your screws aren’t the weak link in your next job.

FAQs

-

Why should I choose stainless steel screws instead of standard zinc or galvanised ones?

Stainless steel screws offer superior corrosion resistance, especially suited to damp, external or exposed settings. They protect against rust and staining and often last longer than standard coatings.

-

What grade of stainless steel should I use, A2 or A4?

For general internal and external use, A2 (304-grade) is usually sufficient. For more demanding environments, like coastal zones, swimming pools, and chemical exposure, choose A4 (316-grade) for enhanced resistance.

-

Can these screws be used with different materials like timber, metal or composite?

Yes, there are stainless steel screws designed for timber, for metal frame fixings, for chipboard and composite panels. Just pick the correct type for your substrate.

-

Do stainless steel screws cost more and are they worth it for everyday jobs?

They do tend to cost a bit more than standard coated screws, but for jobs where longevity, visible fixings or corrosion risk matter, the extra cost is often justified. If you’re working outdoors, near water or on long-life installations, they’re worth using.

-

Are there any special installation considerations for stainless steel screws?

Yes, ensure pilot holes are correct for hardwoods or difficult substrates; choose a head and drive type that match your tool; check that you are using the right length and diameter for the load. Also, whilst stainless is tough, using the correct grade and not mixing incompatible metals (which can cause galvanic corrosion) is still important.